描述

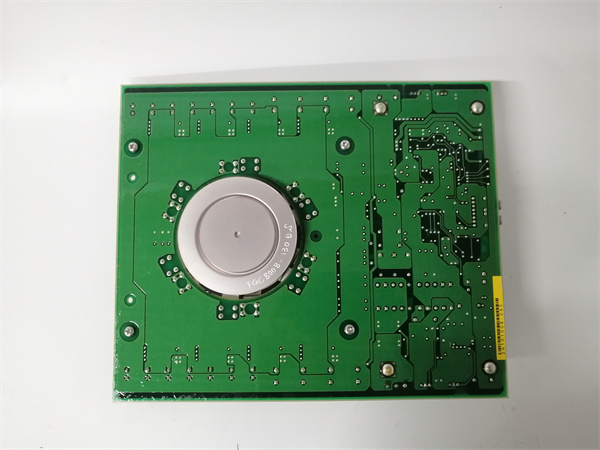

GJR5252200R0101(07DC92F)产品概述

在撑起无数老厂生产的ABB Advant OCS分布式控制系统(DCS)里,GJR5252200R0101(别名07DC92F)就是“连续信号的翻译官”——车间里反应釜的温度、管道的压力、介质的流量这些“看不见摸不着”的信号,全靠它8路AI通道采集、转成数字信号传给中控。要是采集不准,比如温度差0.3℃,化工产品可能报废;压力测偏了,设备还可能超压,所以GJR5252200R0101(07DC92F)的精度和稳定性,直接拴着生产安全和产品质量。

你别觉得“采信号”简单,工业现场的电磁干扰、温度漂移最容易让信号“跑偏”。GJR5252200R0101(07DC92F)就靠俩“硬招”扛事儿:16位分辨率能抓0.01mA的电流变化(比如4-20mA对应0-10MPa,0.01mA就对应0.00625MPa的细微变化);每路还带2500V AC光电隔离,旁边是300kW变频器也不怕。某老化工的苯乙烯反应釜,以前用普通模块,温度误差±0.5℃,换GJR5252200R0101(07DC92F)后,误差直接降到±0.1℃,产品合格率提了5个点。

更贴心的是它对老系统的“兼容性”——很多2000年前后的Advant OCS,原来的模拟量模块要么精度降了,要么通道烧了,GJR5252200R0101(07DC92F)的尺寸、插槽、软件协议和老模块一模一样,拆旧的插新的,DCS自动识别,不用改程序、不用标定,电工半小时就能换完,比换整套DCS省几十万,这也是老厂师傅认它的原因。

主要特点和优势

多信号兼容,一块顶三块:普通模拟量模块要么只认4-20mA,要么只接PT100,现场换传感器就得换模块,费钱又麻烦。GJR5252200R0101(07DC92F)的8路AI每路都能独立设信号类型——测温度接PT100,测压力接4-20mA,测液位接0-10V,一块全搞定。某电厂锅炉监测,以前用3块模块,换2块GJR5252200R0101(07DC92F)就够了,控制柜空出2个插槽,接线少一半,查故障也快。

高精度采集,数据不飘不偏:工业控制最怕“测不准”,比如制药厂冻干机,真空度差0.1Pa就影响疫苗活性。GJR5252200R0101(07DC92F)25℃时精度±0.1%满量程,采4-20mA信号误差不超0.02mA。某制药厂用它采冻干机真空度(4-20mA对应0-100Pa),误差稳定在0.05Pa内,比普通模块高10倍,疫苗活性合格率从96%提到99.8%,每年少浪费几十万原料。

强隔离抗干扰,车间环境扛得住:车间里电机、变频器多,电磁干扰能让普通模块信号“忽高忽低”,中控没法调参数。GJR5252200R0101(07DC92F)每路带2500V AC光电隔离,相当于给信号装“防火墙”,旁边是200kW轧机电机,采的油压信号也稳。某钢铁厂轧机液压系统,换这模块后,油压波动从±0.2MPa降到±0.05MPa,轧钢厚度偏差从±0.1mm降到±0.03mm,次品率降70%。

老系统无缝换,升级不误工:老Advant OCS用户怕换模块要停机改程序,GJR5252200R0101(07DC92F)完全不用——尺寸和老模块一样,插进去就卡紧;软件上DCS自动识别,不用重新组态;接线端子位置都没改,拍张线序照片就能接。某炼油厂常减压装置换6块模块,只用1小时,换完直接开机,没影响当天产量。

这里涉及的核心术语:分布式控制系统(DCS)、模拟量输入(AI)、光电隔离(Optical Isolation)、分辨率(Resolution)、满量程(Full Scale)、采样速率(Sampling Rate)、电磁干扰(EMI)、PT100热电阻(PT100 RTD)、4-20mA电流信号(4-20mA Current Signal)、0-10V电压信号(0-10V Voltage Signal)。

The ABB GJR5252200R0101(also known as 07DC92F)is a high-precision analog input module tailored exclusively for ABB’s Advant OCS Distributed Control System(DCS),a cornerstone for continuous signal monitoring in legacy industrial facilities.Its 8 configurable AI channels support diverse signal types—4-20mA,0-10V,PT100,and RTD—eliminating the need for multiple single-function modules,thus simplifying system integration and reducing cabinet space.

Boasting 16-bit resolution and±0.1%full-scale accuracy at 25°C,this module captures minute signal variations critical for quality-sensitive processes,such as pharmaceutical freeze-drying or chemical reactor control.Each channel features 2500V AC optical isolation,ensuring robust immunity to Electromagnetic Interference(EMI)from high-power equipment like inverters and motors—common in steel,power,and chemical plants.This isolation minimizes signal drift and false readings,enhancing operational safety and process stability.

Fully compatible with legacy Advant OCS hardware and software,the ABB GJR5252200R0101(07DC92F)enables seamless retrofits with minimal downtime.Its wide operating temperature range(0°C to 60°C)and durable construction ensure reliable performance in harsh industrial environments,making it an indispensable solution for extending the lifecycle of aging DCS systems while upholding stringent process control standards.

应用领域

在化工行业反应釜控制中,GJR5252200R0101(07DC92F)是“精度管家”——苯乙烯反应釜要控温80℃±0.1℃、控压2MPa±0.02MPa,模块4路AI接PT100测温度,2路接4-20mA测压力,2路接0-10V测进料量,数据实时传中控,中控精准调阀门。换这模块后,温度波动从±0.5℃降到±0.1℃,压力波动从±0.05MPa降到±0.02MPa,产品纯度从99.5%提到99.9%,每月多产高纯度苯乙烯30吨。

电力行业锅炉监测里,GJR5252200R0101(07DC92F)也顶用——200MW机组锅炉要测蒸汽温度、给水压力、烟气氧含量,模块3路接PT100测蒸汽温度,2路接4-20mA测给水压力,2路接4-20mA测烟气氧含量,1路接0-10V测引风机流量。以前用普通模块,蒸汽温度误差±0.3℃,热效率低;换后误差降到±0.1℃,中控调燃烧器更准,热效率提2%,每年省煤1200多吨,省近百万成本。

制药行业无菌生产中,GJR5252200R0101(07DC92F)是“质量保障”——疫苗冻干机要控真空度0-100Pa、搁板温度-50℃~+50℃,模块2路接4-20mA测真空度,4路接PT100测搁板温度,2路接4-20mA测冷阱温度。换这模块后,真空度误差从±0.5Pa降到±0.05Pa,搁板温度误差从±0.3℃降到±0.1℃,疫苗活性合格率从96%提到99.8%,每年少浪费近百万原料。

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

联系人:白荣

联系人:白荣 电话/Phone:+86 18150087953

电话/Phone:+86 18150087953 邮箱/Email:

邮箱/Email: QQ:340565517

QQ:340565517